Creating & Launching a DTC Brand: 1st Round Design, Development and Marketing Lessons

In 2024 I tried making my own DTC brand. This is a recap of the journey and the biggest lessons I learned along the way. It starts from trying to manufacture an original design locally, outside of China, to pivoting quickly to Chinese production and then eventually launching it in Thailand.

Motivations

Diversify my income. The issue with my current work is that when I get unwell, there's no one to handle client work for me. I've tried training people, but it's been super difficult. I figured the problem here was that ads management is a difficult product to deliver, whereas eCommerce is mostly operations (from my experience).

Physical products vs digital services. I’ve also wanted to move away from digital services as the only thing I do. I’ve worked with hardware in the past and loved it. I often wish I could get back to doing more with physical goods.

Learn by doing. While I had some level of success doing eCommerce back in 2013, it’s been a long time. I so wanted to do a "full rotation" of practice. Just block-headedly go through all the motions to complete a project, even if I know that the project is going to be completely crap - to learn what needs to be learned rather than getting stuck in over thinking zone.

I got a huge boost in motivation here from my friend MotoMatic who has great success in developing and marketing his own designs. He encouraged me to not be the midwit over complicating it (above) and just push through and learn.

Choosing a Product

The first two months after registering my company were spent considering importing and distributing a friend's Korean cosmetics brand. My rationale was solid—I'd seen unauthorized resellers already operating in Thailand, indicating demand, plus I had a direct connection with the founder.

One of my team, Rei, did most of this and a fantastic job. However, after researching all the required processes, we discovered it would cost around $6,000 USD due to Thai FDA approval requirements and specialized warehousing needs. That was a non-starter.

↔️ Weighing my options, I remembered the primary purpose of this venture was learning. So I pivoted to creating my own brand instead.

I'll admit I got a bit idealistic here. I wanted to sell something that provided net positive value to the world - not just trinkets and junk. With a friend's help, I profiled Redditors' favorite purchases and decided on sleep products, starting with a sleep mask to sell locally and abroad.

The product didn't need to be a home run at this stage; it just needed to be a strong exercise in the entire process to gain that experience and understanding. So I committed to completing the process with this category and product.

The Design & Manufacturing Process in Thailand

I used the "double diamond" design process to guide my research, development, and manufacturing approach:

Research & Analysis: I analyzed feedback about sleep masks on Amazon (reviews of top sellers), Shopee, and Reddit to understand which designs people liked, disliked, and why. This gave me probably 1,000+ data points to work with.

Market Research: I analyzed price points locally and internationally using Shopee and Amazon.

User Definition: I defined my target user as women aged 30-40, motivated by health and beauty concerns.

Problem Identification: I established six specific "problems" that my product would aim to solve, based on the review data points. I’ve got it stored in a Chat GPT log somewhere…

Competitor Analysis: We ordered and reviewed 15 sleep masks from existing OEM suppliers to understand the market. We took turns testing each at night and checking which ones we liked and didn’t like, what the problems were, etc.

Prototyping: We established a first prototype vision - not a sketch, but more of a "Frankenstein" of existing products with improvements. Basically, the best part of this with the best part of that.

Manufacturing Partnership: Rei contacted around 10 local manufacturers specializing in textile and foam products. One local manufacturer (a personal contact) agreed to create our design pattern and prototype.

The pattern maker from the factory basically took a list of our requirements and preferences and made the prototypes form there. They were very gracious and patient with us during the process. And allowed me to make several designs with them.

Basically we’d give them a numbered list in a Google doc of what we were looking for plus a visual example of the thing, if possible.

Initially, the results were pretty discouraging. I felt like I was never going to make it and I was just wasting my time while making a fool of myself. But I allowed us to keep trying a few more prototypes and they eventually started looking much better.

Finally, we got a prototype that looked good enough to present to real potential buyers. Initial tests with people in our office was promising - our design was preferred (in style) over all the other masks we had purchased.

During this process, Rei and I kept cost a feasibility analysis going with conservative figures, initially assuming Chinese production. The target numbers were based on a net 30% net margin goal, including all selling and marketing expenses.

But this led us to hit our first major obstacle: the cost estimate for minimum order quantity (MOQ) came out at $8 USD per piece, significantly higher than our maximum target cost of $7.50 (for a $35 USD sale price). So it wasn’t going to leave much, or any substantial margin left at that point.

Also, this prototype had a major flaw. It was too hot when worn for extended periods. This seemed to be related to the fabric we used as a "blackout layer."

So we requested the next version with a replacement for this component which seemed to fix the problem. Phew.

Eventually, we got production costs on target too by cutting down on other luxurious, ensuring each component was priced properly to maintain a 30% net margin.

We received three more samples from the Thai factory to confirm some minor changes and color options, ready for photography. These were preferred by our office testers 4 to 1 against existing designs from China. Finally something we could run with.

Or so I thought.

The Quality Roadblock

Looking more closely at our samples, I noticed inconsistent quality between them. The velcro broke on one, the nose cut was inconsistent, and the finishing at the back wasn't smooth. It was difficult to commit to a full order knowing that perhaps 30-50% could turn out subpar or break during normal use.

(And a good thing we made this call too. A friend later mentioned that the nose degree on masks in China is allowed to be only something very small, like 1%. Whereas our supply chain here locally seemed to be not suited to meeting the same standard).

I felt pretty discouraged until I remembered my friend’s advice to just go with an existing Chinese design and supplier, then iterate on a custom mask later in the background. The project was taking too long, so I bit the bullet, changed track to a Chinese supplier, and essentially restarted the whole setup process.

From basically 0 again.

We sourced three existing designs from Chinese manufacturers, though none were particularly impressive at first. This was a significant setback, but we managed to switch quickly to a reliable supplier who could meet our quality requirements.

The delivery of our minimum order quantity (100 pieces) came to Thailand and was surprisingly painless. We also secured a local Thai supplier for the mask bags and boxes, which turned out much nicer than expected.

We also had a local supplier for the mask bags which was easy to deal with and made in Thailand. The boxes also turned out much nicer than expected, too!

Unfortunately, not everything survive the transition from idea to reality. the fancy packing paper and stickers we had designed proved impractical, resulting in a small waste of time and money.

Building the Brand Identity

Creating a distinctive brand identity was a crucial part of the process:

Naming: We decided on the brand name "Lullara" (pronounced "Lu-lah-rah"), derived from "lullaby." Later, we simplified it to "Lulara" (Lu-la-ra) for easier pronunciation and secured the domain lularasleep.com.

Brand Character: We developed a mascot character named Lara, an otter, to improve brand distinctiveness and engagement.

Visual Identity: We created mood boards to explore the look and feel of the product and branding style, working with a local Thai designer who developed logo concepts.

We settled on a style that I hoped conveyed a premium, cozy, and easily recognizable look:

Packaging Design: And we finalized the pattern for the packing paper to make the unboxing experience cool.

During this period, I also did the basic setup tasks:

Set up Stripe payment processing PayPal.

Established a bank account and discovered that business debit cards are uncommon in Thailand during a company's first year - in fact, some people still don't have them after a few years!

Onboarded with PEAK accounting (a Thai version of Xero).

Created an official LINE account for customer communications.

Product Photography

We A/B tested photographers in Thailand from Fastwork (a local Thai version of Upwork). The cost was extremely reasonable - approx 2,000 THB ($60 USD) each for around 10 photos.

We provided them with a detailed brief including a shot list (in Canva, I think?) with examples and background materials on the brand to establish the desired look and feel.

A key learning here: photographer style matters tremendously. Male photographers seemed to struggle with capturing the "feminine" style we were aiming for, so we received some questionable shots.

However, we also got some excellent photos that captured our brand aesthetic a bit better.

I got help and then spent half a day putting everything together, packaging about 65 out of our 100 units into the final product presentation.

Warehousing

In the beginning, I wanted to go with a 3PL warehouse so that I wouldn’t have to handle stock. Sure, it might flop (and it did) but if things did work, I have a full-time role managing Meta ads for people so I didn’t have time to run around posting stuff.

But ultimately, someone from the team volunteered to handle product storage and fulfillment (pick, pack, and send) in exchange for a prorated fee comparable to what we'd pay a third-party logistics provider elsewhere. So that was a win-win.

To pack the products once all the components were delivered, I got help so it ended up being about 4 of us trying to assembly everything. It took wayyy longer than expected, so we only managed to do about 65 in half a day.

But at least it was stored and ready to sell!

Launch and Promotion

We made our social media accounts across TikTok, Facebook, and Instagram, where we tried some "build in public" style posts along the way to warm things up. One post garnered 15 votes, which was encouraging.

We also looked up and reached out to 100 influencers in Thailand to build relationships for future product promotion.

Unfortunately, the manufacturing delay meant we had a short window to complete everything before the major sales period, and we missed it. This taught me an important lesson about timing in retail.

Another unexpected challenge: Lazada (the 2nd? biggest Thai eCommerce platform) has a cooldown period of 3-5 business days while they confirm your legitimacy before you can promote anything. This includes allowing tracking via Google, Facebook Ads, etc. This meant we couldn't gather reviews before launching, though we did go live in early December.

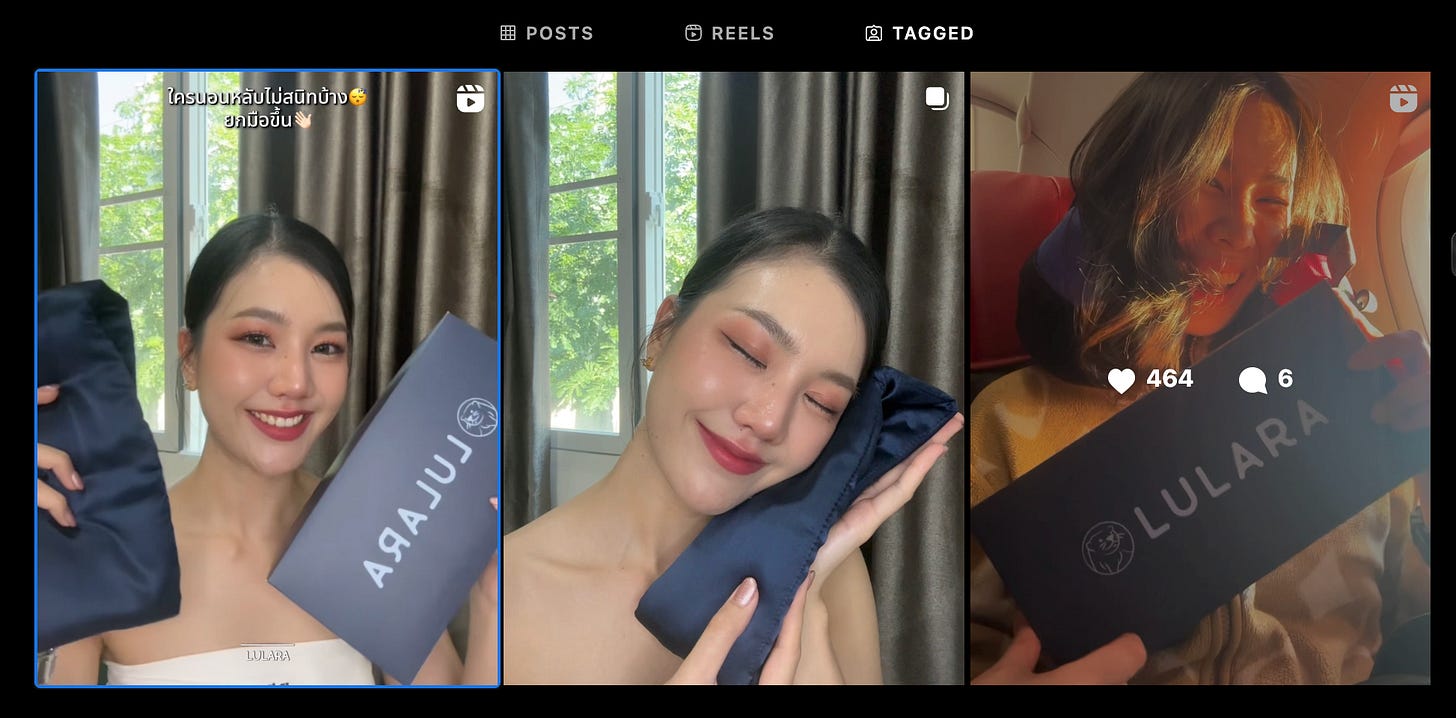

Despite these setbacks, we managed to get 15 influencers to promote the product (in exchange for free product), with approx 5-8 more on the way. Some influencers generated good engagement (likes - see above), though the impact on sales didn’t really come through.

We got 1 sale. And some expressions of interest.

But ultimately the feedback we got over and over again was the price (1,200 THB) was far too expensive.

Originally, I was going to do my own ads on this, though I’m not an eCommerce advertiser, but unfortunately in 2024 I basically burned out and needed to simplify what I’m working on for the time being. So for now the project is paused here.

Costs

Annoying for this article to not give more detail, I know, but I calculated the costs that went into the materials, designs and materials and it was about $1,500 USD.

May update this once I find the final spreadsheet. Doesn’t include labour.

Reflections and Lessons Learned

This has been a LONG process, but as an Aussie friend here mentioned, "not that long, you whinger." Here's the timeline:

May 2024: Company registered.

Months 1-2: Investigated importing an existing brand (later abandoned).

August: Decided to "go through the motions" of creating a DTC brand to see what I didn't know, update my experience in eCommerce, and test some ideas.

Late October: Switched to Chinese manufacturing, restarting the sourcing process.

December: Launched in Thailand via Lazada.

What I Got Right

Some of my initial hypotheses proved correct:

Operating from Thailand IS cost effective AND can produce quality work. Thai people are an under-rated outsourcing talent group.

eCommerce is indeed easier to run semi-absentee compared to service businesses.

Rei has effectively run the whole show with my direction and funding - I've been focused on getting my act together on the ads business. She’s brilliant btw and available for hire, so email me for the connection.

eCommerce fulfillment is much simpler than client services (so far).

Physical product problems are genuinely more fun to deal with than client service issues.

What I Learned

But there were also some hard lessons:

OEM vs ODM. It's MUCH easier and faster to pick and customize an off-the-shelf OEM product than to design your own (ODM)

Product selection. As many experienced friends mentioned, product selection is exceedingly difficult.

Test, test, test. Testing quickly as a means of product discovery is a skill I need to develop in this business.

Inventory risk. This is a serious downside - you don't want capital tied up in unsellable or slow-moving stock as one of my friends warned me.

Looking back, it's clear that unless I already had a winning idea somehow, creating a custom design with fancy packaging and pieces wasn't worth the trouble. While I'm not comfortable selling products I don't 110% believe in myself just to find a winner, though I'm working on that mindset. Maybe I can or can't get over that?

Similarly, developing a brand before discovering a viable product was backward. Having a "nice" brand actually made me less comfortable about potentially tarnishing it with aggressive product discovery experiments. What a error.

What’s next?

I’m happy that I did this project and I have learned an absolute tonne. It’s kinda a wimpy way out, but I did sorta achieve my objective of learning by doing? Just… didn’t really sell anything with an organic-only launch. Haha. 😂

So I’m weighing my options now. I could…

Invest the time in another thing. Sell the brand if I can.

Take the existing product try a different market? E.g. US, Australia, etc. with better spending power.

Try a different product in Thailand with the same brand with a much, much lower price but more promotion via ads, organic, etc.

So if you’ve read this far, what would you do?

$1500 - $2k is crazy worth the lesson from having concept to delivery.

good on you for doing it.

wish I wouldve known before wifey bought a similar facemask not too long ago lol.